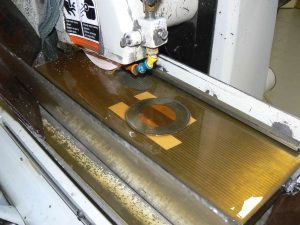

Surface grinding is a widely used abrasive machining process in which a spinning wheel covered in rough particles (grinding wheel) cuts chips of metallic or nonmetallic substance from a workpiece, to produce a smooth finish on flat surfaces. Surface grinding is the most common of the grinding operation. It is a finishing process that uses a rotating abrasive wheel to smooth the flat surface of metallic or nonmetallic materials, to give them a more refined look or to attain a desired surface for a functional purpose. Typical workpiece materials include cast iron and mild steel. Other materials are aluminum, stainless steel, brass, some plastics, ceramics and composite materials.

Some of the applications for our precision-ground components include assemblies, critical parts, precision components, and production parts for various high tech industries, such as the aerospace, defense, automotive, medical, technology, and oil field industries.

Materials

Steels

Stainless Steels

High Speed Alloys

Tool Steel

Ceramic

Many More

Outside Processing

We take care of all special processing including: Heat Treating, Plating, Magnetic Particle Inspection, Nital Etch, Passivation, Brazing, Welding, etc. Grinding service on Cad, Chrome, and Nickel plated surfaces.