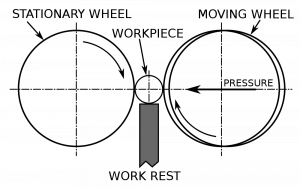

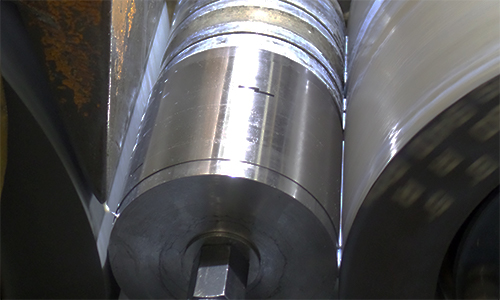

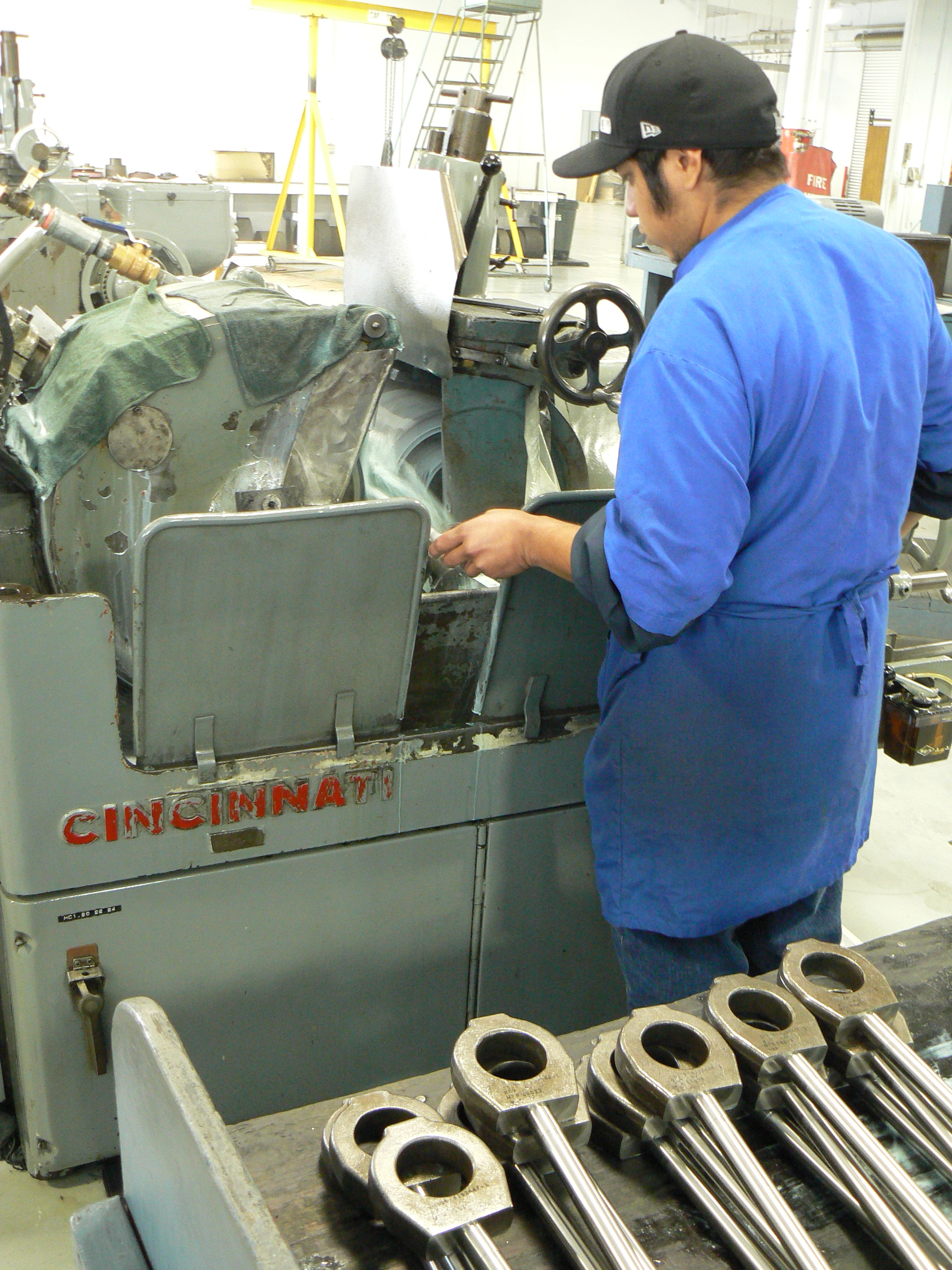

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. Centerless grinding differs from centered grinding operations in that no spindle or fixture is used to locate and secure the workpiece; the workpiece is secured between two rotary grinding wheels, and the speed of their rotation relative to each other determines the rate at which material is removed from the workpiece.

Centerless grinding is typically used in preference to other grinding processes for operations where many parts must be processed in a short time.

Capabilities

Tolerances as low as .000050

Multiple diameters

Infeed and Thrufeed

Materials

Steels

Stainless Steels

High Speed Alloys

Tool Steel

Ceramic

Many More

Outside Processing

We take care of all special processing including: Heat Treating, Plating, Magnetic Particle Inspection, Nital Etch, Passivation, Brazing, Welding, etc. Grinding service on Cad, Chrome, and Nickel plated surfaces.